- Sewer Services > Renovation > Lateral connections

Lateral connections

Connection area problem zone

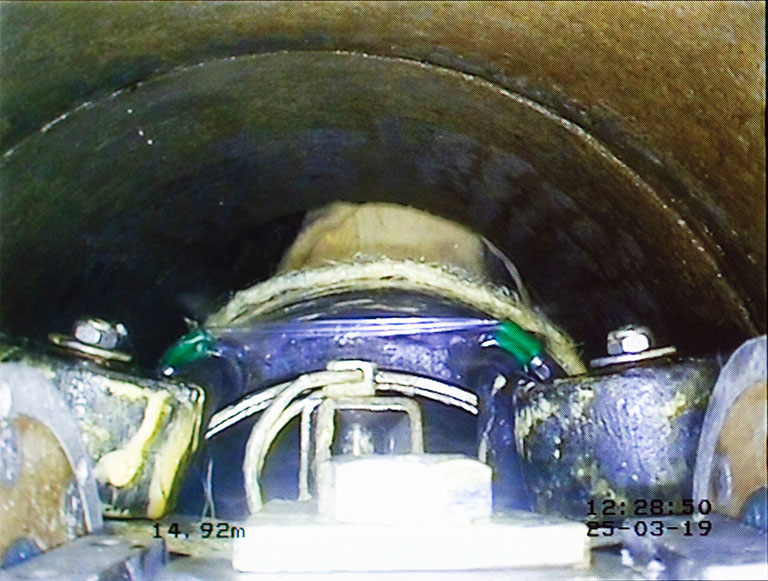

Hat seals/Hutliner® to repair lateral connections

Connections are frequently not incorporated professionally into main pipes. Connectors intrude into the sewer and thus reduce the pipe cross section, or the connections have leaks and thus allow external water to penetrate the sewer network or vice versa, dirt and mixed water seeps out of the sewer into the ground. With hat seals/Hutliners®, these defects can be closed permanently. Hat seals are frequently placed into the main pipe in addition to the inliner lateral connections.

Hat seals/liners are assembled with a special device, the HutlinerPacker®. The HutlinerPacker® presses the hat, which has been saturated in synthetic resin, into the connection pipe opening. Once the resin has hardened, the HutlinerPacker® is removed. The hat closes the previously leaky connection and forms a permanent bond with the connector. The corresponding preliminary work such as cleaning, milling protruding edges and parallel video monitoring by an operator are required.

If a connector short liner is also to be placed in the connection area of the connection pipe in addition, the straight bubble allows the creation of a seal which goes deeper into the connection pipe in addition to the hat cuff. The straight bubble is suitable for connection pipes with a nominal width of DN 80 to DN 250.

Summary

Proper installation of hat seals/Hutliner®

- Into main pipes of DN 100 to DN 800

- Into connection nominal widths of DN 80 to DN 250

Materials

- Hat seals/Hutliner® made from synthetic felt, fiberglass and synthetic resin

Preparatory and follow-up work

- High-pressure jet

- Milling and cleaning

- TV inspection and final check

- Execution by trained, skilled personnel

Click here to activate marketing cookies and display external content from Youtube.

DIBt approval

For the sewer rehabilitation process designated “HutlinerPacker®” for renovating lateral connections in nominal widths ranging from DN 100 to DN 250, SCHWALM ROBOTIC GmbH was issued the General Building-Authority Approval from the German Institute for Structural Engineering (DIBt).

Download DIBt approval Z-42.3-549

HutlinerPacker® SYSTEM HANDBOOK

Preparation of a HutlinerPacker® and placement of a hat seal or Hutliner® (lateral connection).

The system handbook is a component of the General Building-Authority Approval. It describes how to use the systems components safely and appropriately and how to handle them for sewer rehabilitation in all phases of operations. It also includes important information on how to operate the HutlinerPackers® safely and appropriately. It applies to all of those who use this system and who were also trained by Schwalm Robotic GmbH in how to use the HutlinerPackers®.