Lateral connections are used in sewer rehabilitation to rectify leaks in the embedding area of main lines and the lateral lines that branch off from them. A lateral connection is a combined profile made from a short liner and hat seal. It is assembled as part of a trenchless procedure using robotic systems. During this process, the short liner lines the main line, whilst the integrated hat seal seals the lateral line in the embedding area. This design is based on a composite material: the supporting fabric of the short liner is made from a glass fiber mat, and the load-bearing substance of the hat seal is made from synthetic felt. A 2-component resin that lends the lateral connection its permanent dimensional stability serves as an adhesive bond. So, what do we now need to do to manufacture a lateral connection with a precise fit? How exactly does the resin injection process work? Michael Maul, a specialist in trenchless rehabilitation procedures at Schwalm Kanalsanierung, allowed me to take a peek over his shoulder and shows how the job’s done in four steps.

Step 1: Finding the right measurement

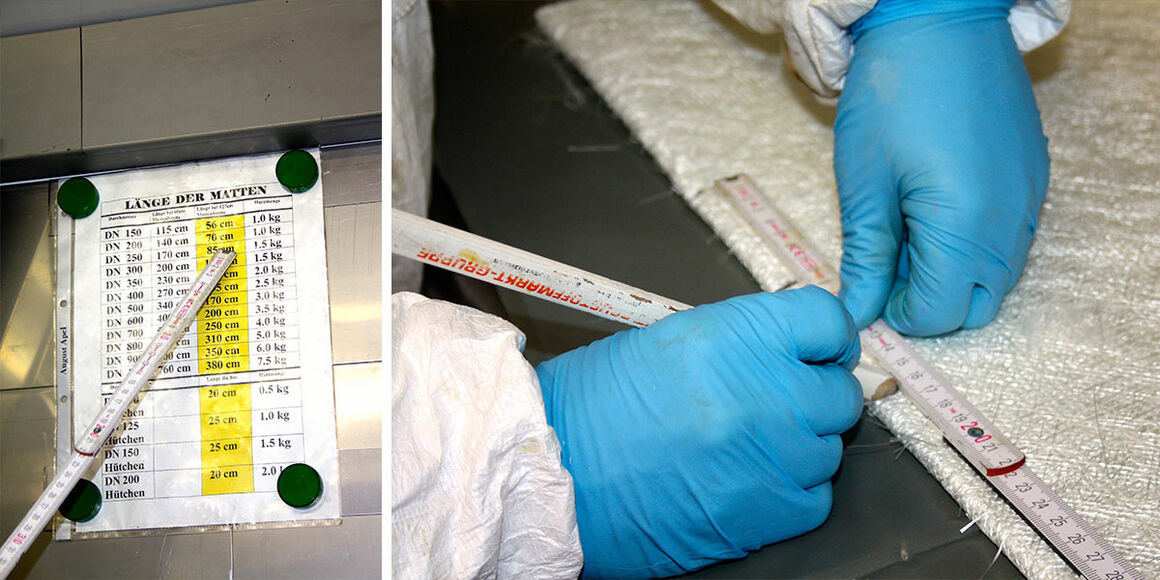

The line dimensions of the main line and lateral line were first of all determined and confirmed using the sewer land register and by examining the construction site. At this point, the following is required for the lateral line: A felt hat matching the line diameter and its branch angle (45 or 90 degrees). For the main line: A sufficiently large glass fiber mat. Felt hats are available as ready-made goods. Glass fiber mats are available as rolled goods and must be individually cut. Measurement tables make your work easier and increase accurate repeatability thanks to clearly defined guidelines. Continue reading under Details if you'd like to find out more.

Details: The glass fiber rolls used by Schwalm are 127 cm wide. For a DN 250 line (featuring a diameter of 250 mm or 25 cm), cut 85 cm of glass fiber mat from the endless roll. Now, lay down and fold the mat at both sides, so that double the thickness is achieved. Note for specialists: the two red and green stripes in the fabric indicate the direction of the chaining thread. But now, how do you get to this 85 cm?

Here's the solution: To precisely and geometrically determine a line's circumference, multiply the line diameter by pi (3.14). The mat must also overlap slightly, so that a positive-fit circular profile can be created. You need an allowance for this reason. A hem allowance, so to speak. Our glass fiber mat for a DN 250 line has an edge length of 85 cm (25 cm x 3.14 = 78.5 cm + 6.5 cm allowance). Michael Maul refers to the table with his foot rule. As I said, you work with measurement tables. Nobody simply sits there and performs a precise calculation with pi. But knowing what's behind it naturally creates clarity. It's better that you know what you're doing.

Step 2: The circular cut-out for the felt hat

The glass fiber mat now requires a circular cut-out for the felt hat, as the lateral connection is a combined profile made from a hat seal and short liner. And this glass fiber collar size must therefore be big enough to also hold the cylindrical felt hat. The images below provide clarification on this matter.

Details: For step 2, the once-folded glass fiber mat is folded once again towards the red and green stripes. It is therefore four times the thickness now. Michael Maul now cuts a semi-circle in the center of the folded edge. The diameter of the semi-circle corresponds to the diameter of the felt hat. It's a little like origami. Use this trick to ensure that you don't cut an entire circle. It's easier and creates fantastic results if you work carefully. Opened out again, the entire thing looks like the illustration shown in the picture below. Here, you can see the circular cut-out through which the felt hat is placed later on.

Step 3: Injecting resin

Gradually coat the twice-folded glass fiber mat with resin, working outward from the inside. To this end, first of all fold the upper part of the twice-folded glass fiber mat to the side again. If you roll up the two halves that have been folded away, as Michael Maul is demonstrating here, you have a neat working environment in front of you. Being just as careful, soak the felt hat with resin. Distribute the resin evenly over the entire surface using a spatula. Protect your work space and use a piece of foil as an underlay.

Details: Schwalm uses a container of 2C resin that's tailored to the quantities of resin required, thereby countering irritating residues.

Step 4: Attaching the lateral connection to the lateral connection packer

The felt hat and short liner are now both soaked with resin. To prepare for the next step, wrap the rubber sleeve of the lateral connection packer with polyethylene foil to protect from becoming dirty with resin. Now, attach the lateral connection in this order: First of all, place the felt hat over the hat bubble and its press its brim onto the lateral connection body, making sure there aren’t any creases. Now, apply the short liner mat soaked in resin. It's important that the felt brim ends up lying underneath the short liner mat, so that a positive-fit structure is formed on the lateral line. In the image, you can clearly see the suitably cut circular opening for the chosen felt hat format. Additionally attached adhesive tapes hold the still-damp liner material in position.

Now, the lateral connection packer is prepared for line rehabilitation. Using the Talpa sewer rehab robot, the operator maneuvers the lateral connection packer to the repair area in the sewer.

Details: A good tradesman cares for his tool. Lateral connection packers are robust from the moment in time at which they leave our premises. They have a long service life when cared for well, and correctly. The aforementioned PE foil in particular protects the rubber sleeve from resin impurities, which impair elasticity over time. We use PE foil from the roll for the lateral connection packer's body and PE bags for the rubber hat.