A sewer tunnel on the movement area of terminal 1 was pierced by underground steel ropes during the construction work for the annex building A-Plus. The new boarding gate A-Plus opened on October 10, 2012.

Monetary considerations and the schedule prompted Fraport AG to repair the damage with the help of sewer rehab robots. This way, it was not necessary to dig up the runway. The contract was placed with the company Schwalm from Bad Hersfeld, Germany. The work took two and a half weeks.

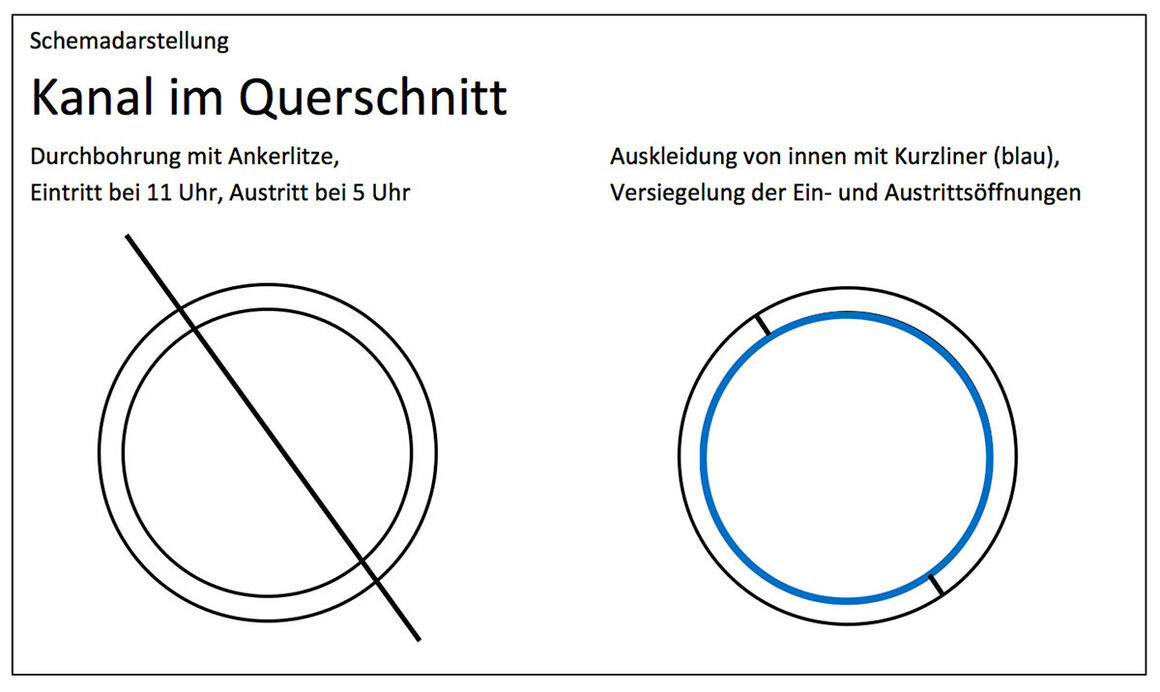

Within the framework of the construction work for the new airport terminal A-Plus, steel ropes were driven into the ground at an angle in order to secure steel sheet piles. Due to negligence, the precise circumstances have not yet been clarified, some of these steel ropes, called anchor cables in trade language, pierced a sewer tunnel running directly in front of the annex building. By way of illustration, you can imagine the cross-section of a sewage pipe: the anchor cables penetrated the pipe at 11 o'clock and emerged at 5 o'clock. This way, these steel cables impaired the free discharge within the sewer. In addition, concrete had penetrated the sewer tunnel through these holes in the tunnel wall. The concrete had been pressed into the ground in order to anchor the anchor cables at their ends according to the dowel principle. The annex building has been completed for a long period already and is waiting to be commissioned. The anchor cables were left in the ground. What was unknown: they had also penetrated the sewage pipe at some locations.

Within the framework of a camera-supported inspection of the canalization, this damage was finally discovered in August 2012. Fraport has the entire airport canalization inspected for leaks at regular intervals in accordance with the self-monitoring ordinance (Eigenkontrollverordnung - EKVO). Within Fraport AG, the business unit Commercial and Tenancy Management is responsible. Jürgen Scheuring, head of the department Demand and Network Management Media, considers the department to be the utility and disposal company for the entire airport operations. He emphasizes that Fraport implements the leading quality standards regarding environmental engineering and efficiency that meet the highest demands.

In order to provide for unobstructed discharge in the blocked sewer section, the steel cable sections crossing the tunnel like tendons initially had to be cut out using a robot. To this end, a compressed air-driven angle grinder was mounted to the working arm of the Talpa FSR 2060 robot used, an all-rounder with the ability to adapt flexibly to any situation. Michael Maul and Reinhard Herwig, both highly qualified specialists for pipeline, sewer and industrial services, performed the work on behalf Schwalm. The specialists worked their way forward in the sewer step by step. A total of six steel cables had to be cut out. The robot was also used to pry out the concrete residues that were completely encrusted in the meantime with the help of a chisel adapter. The affected section of the sewer was cleaned intermediately and the respective waste material was extracted section-by-section. For this, a high-pressure jet vehicle of the company Brauneis from Hainburg near Seligenstadt, Germany, was made available. After the obstructions had been removed from the sewer, the perforated sewer sections were sealed permanently and stabilized from the inside with synthetic resin-soaked ECR fiber glass laminate, so-called short liners. For Michael Maul who was in charge of the trenchless pipe renovation on site, the Fraport deployment was routine.

Christian Englert, construction supervisor of Fraport AG, who supervised the two and a half week long special operation said: "On October 10, 2012 the new boarding gate A-Plus was opened. This sewer tunnel was connected to important building sections. The trenchless method did not only save us from unnecessary stress, but first and foremost saved time and a lot of money, of course."

Fraport AG, Commercial and Tenancy Management, HVM-GT2 Christian Englert, construction supervisor Operations

Operators on the construction site: Schwalm Kanalsanierung, Bad Hersfeld: Michael Maul (highly qualified specialist for pipeline, sewer and industrial services, team manager), Reinhard Herwig (highly qualified specialist for pipeline, sewer and industrial services, assistant)

Kanal-Service Brauneis (high-pressure jet), Hainburg/Seligenstadt: Ralf Brauneis (junior partner, highly qualified specialist for pipeline, sewer and industrial services), Thomas Brauneis (younger brother of Ralf Brauneis, highly qualified specialist for pipeline, sewer and industrial services)